9)

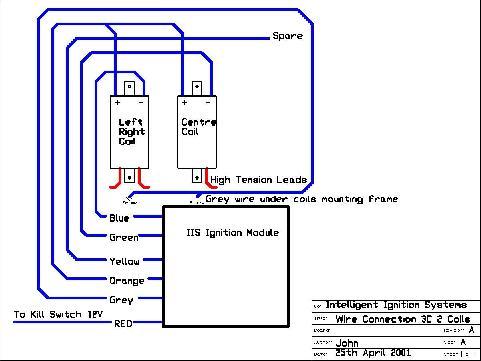

Fit the GREY wire under the frame of the coils Fit the BLACK

wire to the BATTERY Negative terminal, NOT FRAME DIRECT! Fit the RED wire

to the wire disconnected from the coils common wire this is now the supply +12Volt

for the module. See Wiring Harness and Connector data sheet. UNIT DAMAGE will

result if there is a short circuit from earth/frame/Supply to the following Module/coil

wires BLUE, GREEN, ( YELLOW is not normally used on 180's ) check your connections!!!!

If a fuse clears then there is a problem with the wiring do not replace fuse until

you have cleared the wiring fault. UNDER NO Circumstances should the Mauve/Purple

tacho wire be connected to the ignition coils directly or indirectly. It only

drives the electronic tacho, disconnect the tacho from any coil connection you

may have if you use the modules tacho mauve wire. Failure to observe the above

will almost certainly damage the module. NOTE!

The ignition module fires in a sequence of 1-2-3 ALWAYS! therefore any engine

firing sequence is done at the COIL END! This may seem confusing but it is quit

simple to use once the connections are established. See Harness Wiring Detail.

suppliers have this product or RS Components product

10) Fit

New Stator plate/Shaft Encoder to the Engine using the following order:

5 mm Screw-Spring Washer-SS Washer-Stator plate/Encoder. When using stainless

steel screws in aluminium, a small amount of copper grease should used to prevent

"balling" ( thread tearing in the aluminium ). Auto number 557 073.

11) Fit

New Rotor Assembly to the Crank Shaft, locating the indent on the crankshaft

to the set screw located on the new rotor.

12) Check

that the rotor passes through the opto switch slots without contacting

the sides of the slots. This is a fiddly job

and great care must be taken

to ensure reliable operation. If the rotor does contact the sides of any opto

switches the set screws locating

the rotor blade can loosened and the blade

located for correct clearance, retighten the set screws ( these are shipped with

Loctite adhesive on the screws ). If the spacing is not too far off then slight

bending of the actual aluminum Rotor is ok, however check all opto switch clearances

by rotating the crankshaft. The alternator coils now come very close to the magnetic

flywheel outer spider hub ( hence no washers on the supplied screws ) the most

important clearance is the rotor/shutter to bottom of the alternator coils this

should be around 2mm or more, to maintain this clearance the alternator coils

are " spaced " outward to the maximum available, as there may be engine to engine

differences, this operation may require checking and adjustment to get ALL of

the clearances correct. Install the flywheel with locking nut and rotate the flywheel

checking through the spider holes that there is clearance available between the

coils and the inner spider surface....not easy to check...we have found you can

hear it dragging on the coil plastic or even the pole faces of the coils dragging

on the magnet surface proper if they are not correctly spaced as well. The above

operation is only required on the 10mm thick replacement stator plate, we can

supply 6mm or 10mm depends on what is available in Australia at the time.

Once all the clearances are completed and checked, locking adhesive should be

used on the alternator coil mounting screws ie loctite 290. You must stop any

screws loosening in this area due to vibration as severe damage could result from

dislodged parts.

Reconnect the Battery Negative terminal to the engine/frame

Electrical Test and Diagnostics WARNING:

Since the end of 2004, a new module is available. The difference is that there

is no more Red and Green leds, instead there is a number display. This display

not only shows numbers but shows idle low, idle normal and engine above 1235rpm,

by a rising bar in the display. I find this display so easy to see and set the

correct idle as the bar moves up and down.

Test position E now says "1" for

cylinder 1 and 3 triggered with 1000rpm sparks on the Left and Right spark plugs

with the display saying "c" when TDC is found and of course "2" for the centre

cylinder.

Test position F now starts at "1" for 1000rpm and so on to "9"

for 9000rpm and "0" for 10,000rpm.

Test position F drives the coils hard

if you need to test ignition coils for a temperature problem, is ever required.

However test position E is a low power test position and can be used almost for

hours at a time if ever needed, hope i make sense.

The Decimal point on the

display is the power ok signal to the Crank Shaft Encoder module, ie if the decimal

point is ON the Encoder is powered ok. There is no Grey wire at the Ignition Coil

end now, disregard the reference in the docs to any Grey wire.

Fit spark plugs to the ignition coil HT leads, resting on the engine case so they

are visible. a small amount of anti seize copper compound ( grease ) makes plug

removal and fitting less prone to damaging the threads. Auto suppliers have this

product or RS Components product number 557 073. Connect the Ignition Module to

the harness and switch on the ignition. On the module there is a Yellow light

that should be on, and an Orange or Red light on the encoder board, if not, there

is a wiring problem. If ok then turn off the ignition and if not done previously,

fit spark plugs to the ignition coil HT leads and leave them touching the engine

frame. On the module rotate the pointer on the switch to position F see Photo

2 or Diagram 4. Switch on ignition there should be sparks on all the spark plugs,

if so you are doing great! if not all are firing then there is a simple wiring

mistake. Note; The Electronic Tacho and spark plugs will indicate a chronometric

spark rate starting at 1000rpm increasing in 1000rpm steps until 10,000rpm is

reached. This cycle takes about 30 seconds to complete. Any missing sparks ( misfiring

) at the higher spark rate indicates suspect plugs or coils...a very handy test

to help locate misfiring engines and also can be used to " burn clean " fouled

plugs to save removal of tank and plugs when a plug fuel/oil fouls. We use discarded

spark plugs with the earth " tab " broken away giving about a 5m/m spark gap,

this gives an approximate condition for a sparkplug/cylinder under compression,

all our modules support this spark gap at 10,000rpm if you see misfiring at any

point then check for at least 12V available to the module, if ok then the coil/HT

leads/plug caps/sparkplugs are suspect. Email us for tech help if required. It

will then cycle again until position F is DEselected, If your Tacho indicates

any error during this test, then the error is in the Tacho.

Switch off ignition

by using the Kill Switch if Ok then turn off ignition switch. Switch on Kill switch.

Rotate Module switch to position E and turn on ignition. With the crank shaft

at TDC cylinder 1( Right and Left ) the rotor should be half way through the TDC

opto Switch on the encoder board. ( See figure 1 ) This is checked by the RED

light on the module being either ON or OFF, if it is blinking then you are probably

too far to the left and cylinder 1,3 is firing their spark plugs. Rotate the whole

Stator Plate to the LEFT to correct the blinking or to get the RED light to come

on continuously, if the RED light is on all the time then rotate the Stator Plate

to the RIGHT until it goes off. The above procedure is setting the REFERENCE Top

Dead Center (TDC) for the whole ignition system, any error here will give the

wrong signals to the ignition module with poor results the most likely outcome,

take the time to get this right. We have found it to be very precise with just

the slightest of pressure on the crank shaft giving an ON Light going to OFF when

the pressure is released when at TDC. The firing sequence can now be checked by

rotating the back wheel ( or fitting the Flywheel/Magnet assembly ). The first

cylinder to fire after the TDC reference is the Centre cylinder its spark plug

should spark and the Red/Green lights Flash when the rotor moves into the opto

switch no other plugs should fire at this point, if the other plugs are firing

at the same time then there is a wiring fault ( short circuit between BLUE or

YELLOW or GREEN or you are not using suppressor spark plug caps/wiring...naughty

). Continue with the rotation until the correct sequence is confirmed. Switch

the ignition off and rotate the switch on the module to the 0 position or position

6 (depending on what version module you have ).

For

the Hall Effect version this applies;

Rotate Module switch to position E and turn on ignition. With the crank shaft

at TDC cylinder 1 the rotor magnet should be just to the left of the TDC Sensor

Switch on the encoder board. This is checked by using the Red led next to he TDC

switch or as well as the RED light on the Main Module being either ON or OFF,

if the Red and Green are blinking then you are probably too far to the left and

cylinder 1 is firing its spark plug. Rotate the whole Encoder Board to the LEFT

to correct the blinking or to get the RED light to come on continuously, if the

RED light is on all the time then rotate the encoder to the RIGHT untill it goes

off. The above procedure is setting the REFERENCE Top Dead Center (TDC) for the

whole ignition system, any error here will give the wrong signals to the ignition

module with poor results the most likely outcome, take the time to get this right.

Hall Effect at TDC We have found it to be very precise with just the slightest

of pressure on the crank shaft giving an ON Light going to OFF when the pressure

is released when at TDC. The firing sequence can now be checked by rotating the

crank shaft in the normal ( clockwise ) direction and confirm the correct sequence

ie Right +Left Then Centre.

The first cylinder to fire after the TDC reference

is the Centre cylinder its spark plug should spark and the Red/Green lights Flash

when the rotor moves into the opto switch no other plugs should fire at this point,

if the other plugs are firing at the same time then there is a wiring fault (

short circuit between BLUE or YELLOW or GREEN or you are not using suppressor

spark plug caps/wiring...naughty ).

Continue with the rotation until the

correct sequence is confirmed. Switch the ignition off and rotate the switch on

the module to the 0 position. That completes the calibration procedure.

With

the spark plugs fitted to the cylinders, fuel on, ignition on, starter engaged,

there will be flashes on the Modules RED light as the engine cranks indicating

that the trigger signals are being received from the encoder ( the yellow light

stays on all the time that the ignition is switched on ) and the engine should

fire.

The IDLE may have to be adjusted to about 1000RPM after warming up.

Setting the Idle Speed The Tacho as fitted to most Motorcycles is an indicator

not a Scientific Instrument ie; its accuracy can be poor.

On the module 1000rpm

is indicated by the Red Light being on and the Green light just coming on, 1000

to 1250 is indicated by Red and Green on with 1250RPM and above both lights go

off. 0-1000RPM 1000-1250RPM 1250-8375RPM 8375 and up Red Flashing Red and Green

on Red and Green off Red on= RevLimit

The different curves may be selected

while the engine is running. Positions 0 to B only. Please Note on the dual 120/180

module's position 6 to B are for the 180 selection 0 to 5 are for the 120.

If your Ignition module connector has ID120 or ID180 written on it, then the correct

firing sequence is automatically loaded. You may use 0 to 5 for both 120 and 180

and 360. e.g. the 180 equivalent of position

0 = 6 Low Advance, early rev

limiter

Curve 0 1 = 7 Medium Advance, 8375RPM RevLimit

Curve 1 2 = 8

General Purpose, easy advance

Curve 2 3 = 9 Performance engines only!

Curve 3 4 = A Simulates "Original" 180 Advance

Curve 4 5 = B High RPM Retard,

typically free flow exhausts

Curve 5 E = Encoder (Crank Shaft ) test for

120 and 180 F = Spark test on all cylinders 120 and 180 C and D are for future

use and if selected will give curve 0 all switch positions are valid. Suggestion

only: Select

position 0 to try out the rev limiter at 6500rpm so that you know when it comes

on. Then try position 2 for low octane fuels/lower compression engines. Then try

position 3, if pinking is present, then go back to 2. 13)

Find a suitable mounting point for the TA/TCI module away from engine heat, water

saturated areas, battery acid spills or fumes ( gasses ), etc. An area that has

cool air flowing is ideal. The Module is held in place by Velcro tape ( supplied

) and or a cradle with velcro. There are not a lot of good mounting points on

the 3C/Jota.

|

|

Possible place for the IIs module

|

14) Once you have decided on the appropriate switch settings, Fit the supplied

water proofing boot to the TA/TCI module as per Photo 5 or Photo 6 this boot must

also be sealed by waterproof tape at the bottom edge/ module area, a small amount

of RTV738 silicon sealer around the cable entry/boot point will also be required

to complete the seal. Note; PVC electrical tape is unacceptable for sealing use,

use Gaffa ( Nashua ) or Duct tape only. Also at the ignition coil end of the harness

a small amount of sealer ( RTV738 silicon sealer ) is used at the end of the black

sleaving/wire exit point to stop wind born rain entering and traveling back to

the module connection, this is important. The latest harness has thinner wire

for the coil connections etc. these wires must be fastened down with plastic Ty-Wraps

( or similar ) to prevent vibration failure, again PVC electrical tape is unacceptable

for this purpose, this is most important for the black battery wire from the new

harness, extra sleeving will be supplied to cover this black wire in the future.

How to set TDC Accurately!

TDC

is found by using a stopping device in the plug hole ( we use on old spark plug

body with the porcelain removed and a soft brass bolt in the body ) that stops

the piston just before TDC with a degree wheel attached to the crank shaft its

position is noted on the degree wheel ( a small reference mark on the case will

be the ref. for the relative degree wheel position ) then the crank is rotated

backwards until the piston stops again against the bolt in the spark plug hole.

Its postion is marked on the degree wheel, the bolt is removed from the plug hole

and the postion half way between the two points marked on the degree wheel is

TDC. From this you can now mark a point on the crank case 40 degrees to the right

from the TDC position. With the engine running the crank shaft will move between

these two points when a timing light is attached. Static start/idle is about 6

degreesBTDC rising to a maximum of 38 degrees on curve 3 or 32 degrees on curve

2. You only need to use an actual degree wheel to set the 40 BTDC position. If

you attach any type of disk and know the diameter then 40 degree can be translated

into length on the circumference by using the formule PI*d dividing that length

by 360 and multiplying the resultant by 40 = length of 40 degrees eg 150m/m diameter

times 3.14159 = 471.238 m/m circumference divided by 360 degrees = 1.3089 m/m

per degree therefore this times 40 = 52.35 m/m from TDC to the right is 40 degrees

BTDC. Encoder

details

UPDATE; as of March 2001 we have a new encoder, " Disco

model " it has diagnostic lights on all the cylinder triggers located on the crank

shaft encoder ( C/S ) board. TDC is checked by the Module or directly on the C/S

encoder board, all triggers will light their respective lights when the rotor/shutter

pases through the slot. Unfortunatley this encoder is not compatible with the

previous opto encoder We designed this new unit to facilitate a one ignition module

( I mode ) fits all policy. The I mode 120 ignition module will run ALL Laverda

engine types with either Opto or Hall effect encoders. The benefit is that we

will supply to various owners a spare 120 I mode module as local backup field

failures are rare, however if you are like us, being stranded is unacceptable...a

little preparation will help you on your way. This encoder has a number of field

derived improvements, There is now a small Orange or Red light on the green board

which glows when the Battery Voltage is Between 12 to 15 Volts ( ignition on )

however if the Battery Voltage falls below 12 Volts the light will become progressively

dimmer until at 9 Volts it will be off, the encoder will work down to 7 Volts

Cranking Start with the yellow light on the TA/TCI module indicating all is ok

when glowing. The purpose of this Orange/Red light is to indicate a failing battery

at start time ie; while cranking the engine on the starter motor,

Yellow

on and Red flashing at the TA/TCI with Orange encoder light on = all ok

Yellow

on and Red flashing at the TA/TCI with Orange encoder light off = low battery

volts/difficult starting

Yellow on and no Red Flashing at the TA/TCI with

Orange encoder Light off = do not waste your time, no starter motor starting possible,

Try clutch/bump start.

Yellow on and no Red Flashing on the TA/TCI = no starting

possible, diagnose the problem before you flatten your battery with useless cranking.

No lights on at all, no starting possible Whats

New and Upgrades;

We knew that field upgrades from on going development

would occur, to maintain all installations with the latest improvements all of

the system is plugable ie all encoders can be upgraded on the supplied harness

if you want a later product/upgrade then this can be done for a nominal charge,

for example, to convert from opto to I mode opto/halleffect the encoder is swapped

the rotor/shutter is swapped and inside the ignition module a printed circuit

board is swapped. This requires only limited skills, all removed parts can be

traded back to us. At this point in time we are happy with all advance Curves,

they are stable. UPDATE; as of March 2001 we have a new encoder, " Disco model

" it has diagnostic lights on all the cylinder triggers located on the crank shaft

encoder ( C/S ) board. TDC is checked by the Module or directly on the C/S encoder

board, all triggers will light their respective lights when the rotor/shutter

pases through the slot. Unfortunatley this encoder is not compatible with the

previous opto encoder. We designed this new unit to facilitate a one ignition

module ( I mode ) fits all policy. The I mode 120 ignition module will run ALL

Laverda engine types with either Opto or Hall effect encoders. The benefit is

that we will supply to various owners a spare 120 I mode module as local backup

field failures are rare, however if you are like us, being stranded is unacceptable...a

little preparation will help you on your way. Ignition

Coil Information and technical details

Replacement Ignition coils The replacement of ignition coils on older Laverda

engines is a straight forward selection process. ( the use of a digital multimeter

will help in selecting a suitable coil, they are inexpensive these days ) Primary

resistance, 2.5 ohms and above ( higher ) Secondary resistance, usually between

8K and 14K ohms ( 8000 ohms to 14000 ohms ) The newer " electronic " coil types

are better for digital ignitions due to the fact that the primary and secondary

windings are electrically ( galvanicly ) isolated, meaning you cannot measure

any resistance between primary and secondary connections older coils usually have

around 3 ohms to 14Kohms resistance between primary and secondary connections

Modern multi cylinder engines can have the very new, low primary resistance (

inductance coils ) basically these can only be used on our TCI system. Due to

their very low primary resistance ( .5 to .8 ohms or R5 to R8 ) they will damage

and render inoperative the TA module if used.

Typical after market replacement

coils are the Dyna DC1-1 twin output coils, these are very useful on the 180 configuration

allowing the use of 2 twin output coils. One coil feeds the outer two cylinder/spark

plugs, the second feeds the centre spark plug from one output the other output

is connected to the engine/frame via a High Tension ( HT ) lead, looks unusual

at first however it is a good way of being able to swap coils if a fault is suspected

in an ignition coil. Not generally known is the fact that twin output coils require

the spark plug gap to be reduced on their respective plugs ie .4 to .5mm instead

of the usual .6 to .7mm. This is due to the fact that the total air gap is the

sum of both plugs and can/will stress the ignition coil if too wide. We have available

on our TA a triple coil drive for the 180 engine ie 3 separate coils can be used,

the TCI can also use this mode however two coils must be wired in series. Some

ignition coils are so poorly manufactured that they reflect large voltages back

to the electronic ignition modules that they will damage the module permanently

or leave you stranded, one such type is Bosch GT40 a coil suitable for points

only systems. High

Tension Leads.

The use of silicon carbon ( graphite ) HT leads

on motorcycle engines is not permitted, the graphite fails from the vibration

and starts to arc internally leading to multiple open circuits and the ultimate

failure of the ignition coil due to high reflected voltages into the coil with

internal arcing rendering the ignition coil permanently damaged. PVC or Silicon

leads of 7mm diameter copper wire conductors are the usual type of HT lead used

on motorcycles. These leads then require suppressor caps at the coil or plug end,

typical Laverda equipment are the NGK 5Kohm type ( model type SD05F ) the use

of suppressor caps is not just for interference suppression the real benifit to

motorcyles is the elimination of cross firing ( cross firing can lead to substantial

engine damage if left to continue ) racing engines included!! unless special resistor

spark plugs are used. Inductively suppressed leads are my personal choice, these

consist of stainless steel wire spirally wound on a fiber glass core with silicon

outer insulation and are terminated with stainless steel connections with spring

steel clips covered by high grade silicon water proof boots .....simply the best

choice. These leads do not adapt well to older " spike " style coil HT termination,

although we have several 180's using these leads on Nippon Denso OEM coils on

Laverda's, email us for more detail. Spark

Plugs

We have had no success using Bosch spark plugs on Laverda

engines, poor starting, non existent idle, even on new plugs. Perhaps your experience

is different. We recommend NGK B8ES ( or B7ES for engines prone to oil fouling

). Operating

Instructions

Your new didgital ignition may require a different

starting technique than what was used before. 1) Cold engine, choke is required,

normal starting technique, if engine fails to start first press of the starter

button, wait at least 2 seconds before pressing the starter button again. This

is due to the fact that the IIS module is trying to " learn " what the crankshaft

is doing, if the engine does not start, then a reset period is invoked for 1.6

seconds after releasing the starter button, during this period no engine starting

is possible. A relaxed start operation will result in the engine starting within

2 crank revolutions or within 2 seconds, whichever is less. Constant stabbing

at the starter button is not the best way to start a Laverda. With the IIS module

first press start is all that is normaly required. 2) Warm/Hot engine 180's seem

to start best no choke, 1 to 2 twists on the throttle ( Dellorto pumpers ) press

the starter with a slight opening of the throttle at the same time will start

the engine. As most owners know thier engines well, a little experimentation will

give the best start technique for your engine. 120's seem to require choke at

all times to start reliably, again first time starting is normal for the IIS module.

Post

Installation Problems

After installation of the IIS module some

owners found that there appeared to be " new " problems. Basicly this is due to

a previous poor ignition hiding poor carburettor tuning, after fitting the IIS

module ALL carburettor problems are now VERY evident. We use various tools to

setup the engine after IIS installation ie mercury manometer, ignition control

panel that disables individual spark plugs and measures ignition coil performance.

Setting up the carburettors for us is best done with the manometer or individual

manometer operating on the air intake side if no balance spigot is available,

we set the cutaway to about 6.5mm on the centre carby and the other two also at

6.5mm ( some carbies required 7.5mm ) idle pilot ( air ) screw 1.75 turns out

from fully in ( if you cannot maintain idle use 2 turns out or more....runs very

rich so plugs will carbon foul in a short time ). Blipping the throttle gives

a temporary hign idle, settling after 1 to 5 seconds is an indication of lean

idle pilot. Black smoke at idle...too rich. Blipping the throttle from idle, engine

stumbles then revs clean.....too lean for the transistion phase of the carby...1/8

turn out on the idle pilot.. repeat last procedure until transistion is smooth....probably

runs rich at idle now....welcome to Dellorto's.

Some of the things to check;

Symptom

1) Hole at mid to upper rev range. Float level, needle and seat

check

2) Hole from idle to first gear take off Tricky one this, try 1/8 turn

out on the idle pilot screw....lots of likely causes, email us.

3) Hunting

at constant throttle Check for worn slides

4) Pinking Try going down one

switch position, 2 is a good curve to begin with.

Contact

for enquiries iismail@optusnet.com.au

|

![]()